Heat Sealers – A Beginners Guide

Hand Operated Heat Sealing Machines: A Guide for Beginners

If you are looking for a simple and affordable way to seal plastic bags or pouches, you might want to consider hand operated heat sealing machines. These are devices that use heat and pressure to create airtight and watertight seals on various types of plastics. In this blog post, we will explain what hand operated heat sealing machines are, what plastics and applications they are used for, how to use them, which types or qualities are best and where to purchase spare parts.

What are hand operated heat sealing machines?

Hand operated heat sealing machines are also known as impulse sealers or bag sealers. They are small and portable devices that can be plugged into a standard power outlet and used on a table or counter. They consist of a heating element, a timer, a pressure bar and a handle. The heating element is a thin wire or strip that heats up when electricity passes through it. The timer controls how long the heating element stays on. The pressure bar is a metal or plastic piece that presses the plastic bag or pouch against the heating element. The handle is used to lower and raise the pressure bar.

Other heat sealing machines available on amazon.co.uk

How do hand operated heat sealing machines work?

The basic principle of hand operated heat sealing machines is to melt and fuse the plastic layers of the bag or pouch together using heat and pressure. To use a hand operated heat sealing machine, you need to follow these steps:

- Plug in the device and turn it on. Adjust the timer according to the thickness and type of plastic you are using. You can refer to the manual or the manufacturer’s website for guidance.

- Place the open end of the bag or pouch between the pressure bar and the heating element. Make sure there is no air trapped inside the bag or pouch.

- Press down the handle to lower the pressure bar and activate the heating element. Hold it for a few seconds until the timer goes off.

- Release the handle and lift the pressure bar. Wait for a few seconds to let the seal cool down and harden.

- Remove the sealed bag or pouch from the device and check the seal for any gaps or leaks.

What plastics and applications are hand operated heat sealing machines used for?

Hand operated heat sealing machines can be used to seal various types of plastics, such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polyester (PET) and laminated materials. However, not all plastics are suitable for heat sealing, as some may melt, burn or warp under high temperatures. You should always test a small sample of your plastic before using it with a hand operated heat sealing machine.

Hand operated heat sealing machines can be used for various applications, such as:

- Packaging food products, such as snacks, nuts, candies, spices, coffee, tea, etc.

- Packaging non-food products, such as cosmetics, jewelry, crafts, hardware, etc.

- Sealing medical supplies, such as bandages, gauze, gloves, etc.

- Sealing documents, photos, cards, etc.

What to consider when buying a hand operated heatsealer

There are different types and qualities of hand operated heat sealing machines available on the market. Some of the factors that you should consider when choosing a hand operated heat sealing machine are:

- Size: The size of the device determines how wide of a seal you can make. You should choose a size that matches your bag or pouch dimensions.

- Power: The power of the device determines how fast and strong of a seal you can make. You should choose a power that matches your plastic thickness and type.

- Features: Some devices have additional features that can enhance your sealing experience, such as adjustable timers, temperature controllers, cutters, magnets, etc.

- Durability: The durability of the device depends on its material quality and design. You should choose a device that is sturdy and reliable.

Where to purchase spare parts for hand operated heat sealing machines?

Like any other device, hand operated heat sealing machines may require maintenance and repair over time. Some of the common spare parts that you may need to replace are:

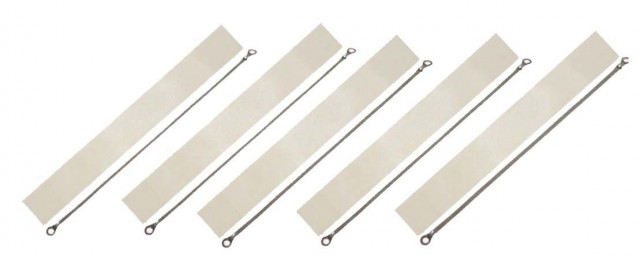

- Heating element: The heating element may wear out or break after repeated use.

- Pressure bar/ Silicon Rubber: The pressure silicon rubber may burn or crack due to excessive use or misuse.

- Teflon tape strips: The teflon tape covers the heating element wire and insulates it from touching the plastic bag directly. over time and with use this teflon becomes burned and requires replacement.